- Welcome to, We are a professional factory specializing in the production of testing chamber equipment.

- WhatsApp:+8615112812380

站内搜索

菜单演示

相关推荐

The Fundamental Purpose Simulating Real World Corrosion to Prevent Costly Failures

Salt spray testing exists to replicate how materials and coatings behave in harsh, corrosive environments. This accelerated corrosion simulation helps businesses understand how well metals and protective coatings resist rust and degradation over time. By exposing samples to a neutral salt fog chamber, typically following the ASTM B117 standard, manufacturers can predict real-world performance without waiting months or years.

Why is this important? Corrosion can lead to equipment failure, safety risks, and expensive repairs. Salt spray tests reveal weaknesses early, allowing companies to improve material selection and coating durability. This proactive approach helps prevent costly failures in critical industries such as automotive, aerospace, and construction.

Ultimately, salt spray testing serves as a vital quality control tool. It provides reliable, repeatable data on corrosion resistance, ensuring products meet or exceed industry expectations for durability. At Dexiang, we emphasize this testing as part of a comprehensive strategy to help clients protect their investments and maintain product integrity over time.

Regulatory and Industry Requirements When and Why Compliance Demands Salt Spray Testing

Salt spray testing is often required to meet strict regulatory and industry standards. Many sectors rely on this test to prove that materials and coatings can withstand corrosion in real-world conditions. Here’s why compliance usually demands salt spray testing:

| Regulation/Standard | Purpose | Why Salt Spray Testing Is Needed |

|---|---|---|

| ASTM B117 | Defines methods for corrosion resistance testing | Ensures consistent, accelerated corrosion simulation in a neutral salt fog chamber |

| ISO 9227 | International guideline for salt mist exposure time | Standardizes corrosion testing worldwide for materials and coatings durability |

| Automotive Standards | Safety and durability enforcement | Verifies protective coating performance under harsh weather conditions |

| Aerospace Codes | Requires material corrosion prevention | Confirms metals and coatings meet tough industry requirements |

| Construction Specs | Quality control for metals used in infrastructure | Prevents costly corrosion failures by evaluating coating durability |

Meeting these standards is critical because salt spray testing provides reliable data on how materials behave during prolonged salt mist exposure. Without this test, manufacturers risk producing items that fail prematurely due to corrosion.

In short, salt spray testing isn’t just a recommendation—it’s a must-have for many industries aiming to comply with legal and performance benchmarks. This helps ensure safer, longer-lasting products for customers across the United States.

Key Benefits How Salt Spray Testing Drives Quality Control and Innovation

Salt spray testing is essential for maintaining high standards in corrosion resistance testing. It helps manufacturers and engineers spot weaknesses in materials and coatings before products reach the market. By simulating accelerated corrosion in a neutral salt fog chamber, companies can evaluate the durability of protective coatings and improve them continuously.

Main benefits include:

| Benefit | Description |

|---|---|

| Early Detection | Finds corrosion issues before costly failures |

| Consistent Quality | Ensures materials meet ASTM B117 and ISO 9227 standards |

| Product Improvement | Supports innovation by testing new coatings and materials |

| Cost Savings | Reduces warranty claims and product recalls |

| Compliance Assurance | Meets regulatory and industry-specific requirements |

Using salt spray testing as a part of quality control for metals drives better products with longer lifespans. It encourages innovation by offering reliable data on coating performance, pushing materials to be more corrosion-resistant and cost-effective.

Step by Step Conducting a Salt Spray Test for Reliable Results

Conducting a salt spray test involves clear steps to ensure consistent and reliable data on corrosion resistance. Here’s how it typically goes:

- Prepare the SampleClean the metal or coated item thoroughly to remove grease, dirt, or oils. This ensures the salt mist affects the surface evenly and simulates real corrosion scenarios accurately.

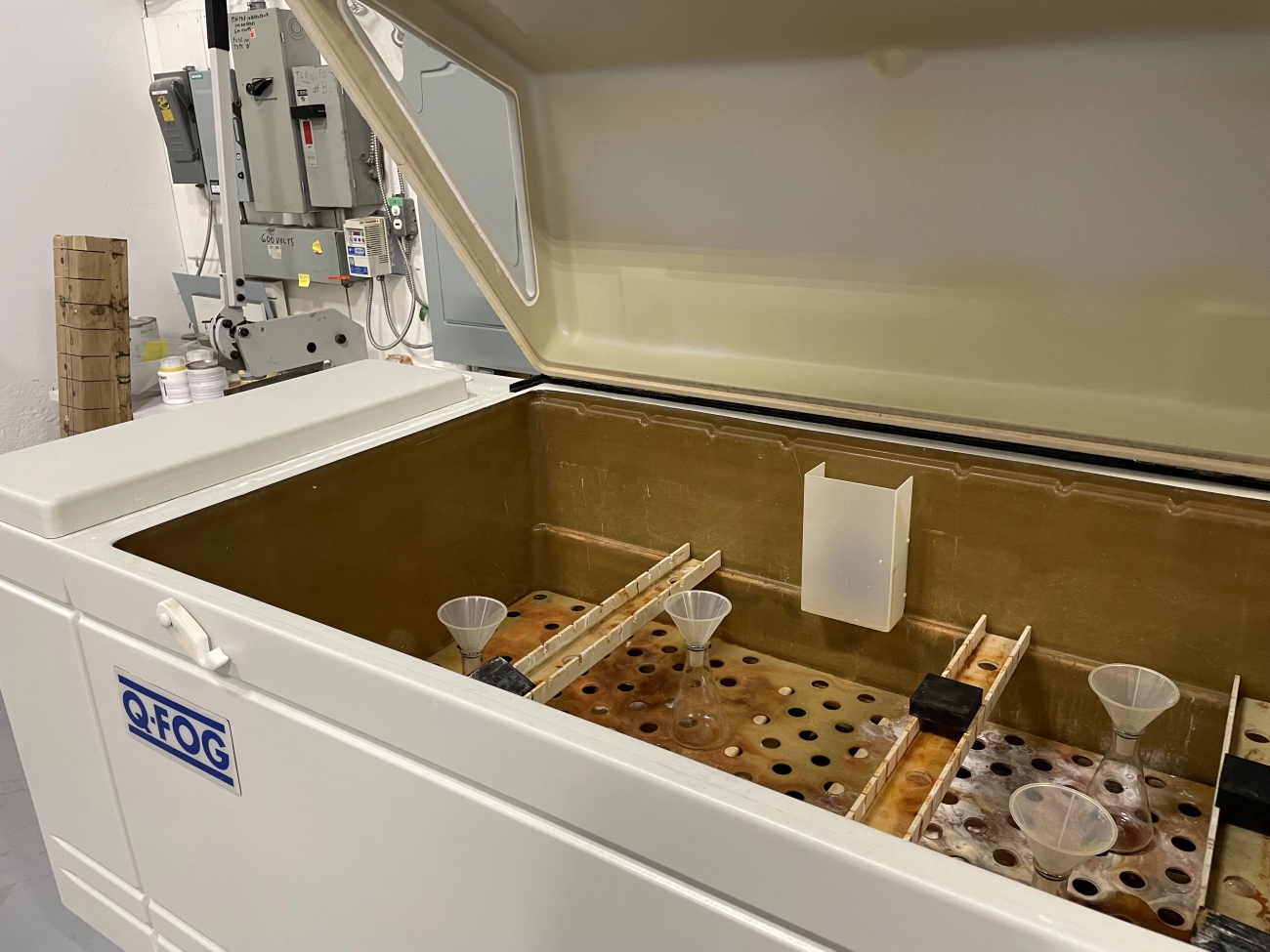

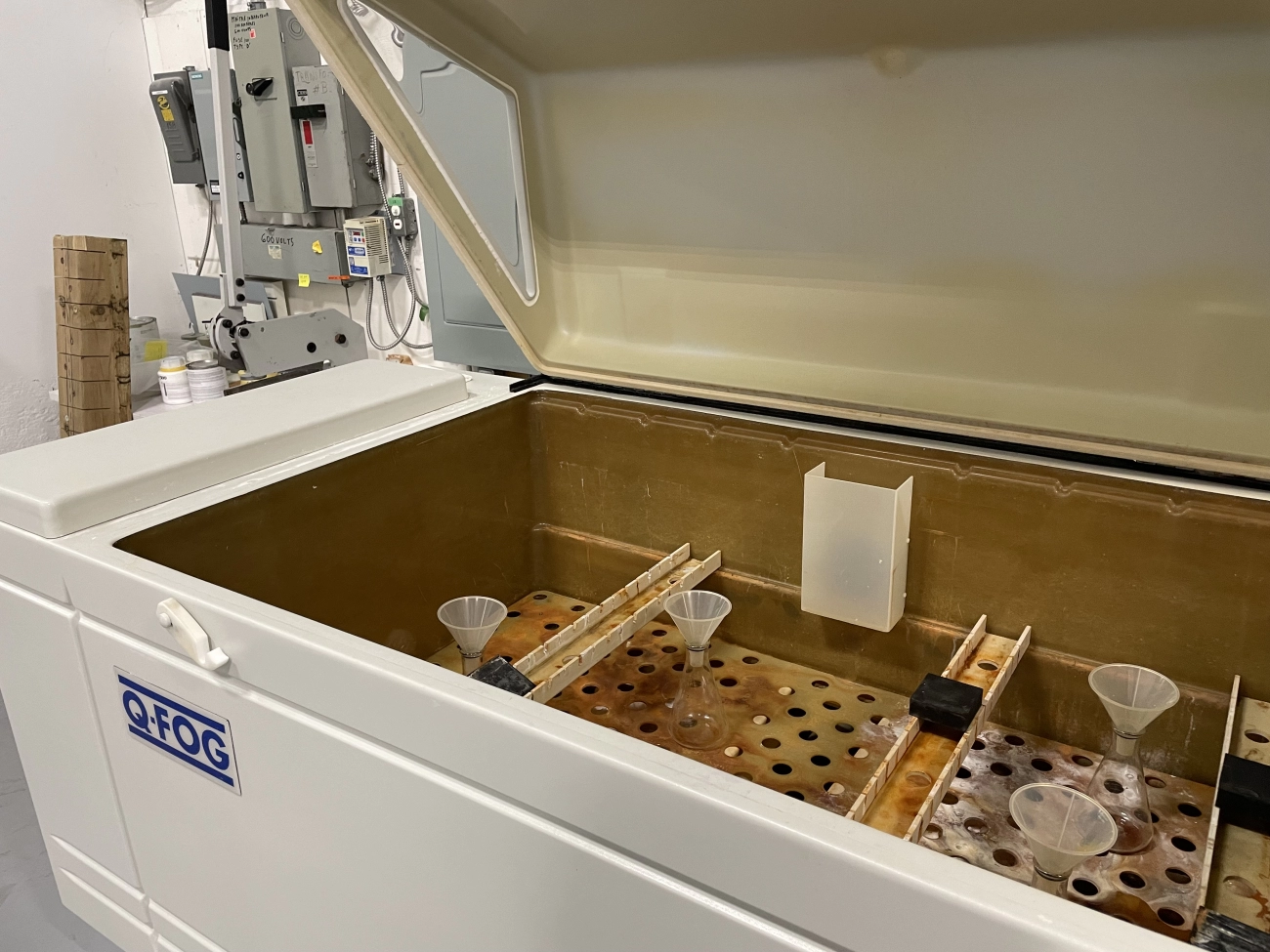

- Set Up the Salt Spray ChamberUse a neutral salt fog chamber that follows the ASTM B117 standard or ISO 9227 compliance. Fill it with a salt solution, usually 5% sodium chloride, to create a controlled salty mist environment.

- Position the Sample CorrectlyPlace your sample at a 15 to 30-degree angle inside the chamber so salt mist can reach every exposed surface. Make sure the specimen doesn’t drip and no liquid pools on its surface.

- Run the Test for the Required TimeSet the salt mist exposure time according to your test plan—this could range from a few hours to several days or weeks, depending on how aggressive the testing needs to be for coating durability evaluation or corrosion resistance testing.

- Monitor Conditions ConstantlyMaintain temperature around 95°F (35°C) and steady salt spray concentration. These conditions accelerate corrosion while keeping results repeatable.

- Inspect and Document ResultsRegularly examine the sample for rust, pitting, or coating failure. Detailed logging helps in evaluating protective coating performance and making material corrosion prevention decisions.

By following these steps, salt spray testing effectively simulates real-world corrosion, giving you quality control data that’s critical for improving metal products and coatings.

Real World Applications Industries Relying on Salt Spray Testing

Salt spray testing plays a crucial role across many industries where metal corrosion prevention is vital. Manufacturing sectors like automotive, aerospace, and construction use this test to evaluate coating durability and ensure their products meet quality control for metals standards. For example, car manufacturers rely on salt spray tests to make sure vehicle parts withstand harsh weather and road salt without corroding early.

In the electronics industry, components often face moisture and salty environments, so corrosion resistance testing helps protect sensitive parts. Meanwhile, oil and gas companies use salt spray testing to assess the performance of protective coatings on pipelines and equipment exposed to marine or coastal conditions.

Even consumer goods such as outdoor furniture and hardware get tested to maintain protective coating performance over time. This testing also aligns with standards like the ASTM B117 and ISO 9227, ensuring products comply with industry requirements and deliver reliable performance.

By simulating accelerated corrosion in a controlled setting, businesses can catch weaknesses early, reduce warranty costs, and innovate better materials tailored to real-world demands. This makes the salt spray test an essential tool for product durability and customer trust in the U.S. market.

As a dedicated environmental test chamber manufacturer, our focus is on supporting China’s manufacturing ecosystem while serving global customers who require dependable, quality testing equipment. Whether you need climatic simulation chambers, thermal shock testing, or corrosion resistance simulation, Dexiang delivers tailored solutions that improve efficiency and test accuracy.

deruitest|chambe

我们是专业的WordPress网站建设团队,提供高品质的WordPress主题。新主题微信公众号:cntestingchamber.com,欢迎热爱WordPress的每一位朋友关注!

相关推荐

- How Many Types of Stability Chambers Are There Explained with Features

- What Is the Purpose of the Aging Test Explained for Manufacturers

- What is the 85 85 Damp Heat Test Guide for Reliable Product Testing

- Incubator vs Environmental Chamber Differences Features and Uses Explained

- What Is an Environmental Test Chamber How It Works and Key Features

© 2025. All Rights Reserved. cntestingchamber.com Theme By XinTheme