- Welcome to, We are a professional factory specializing in the production of testing chamber equipment.

- WhatsApp:+8615112812380

站内搜索

菜单演示

相关推荐

If you’re working in pharmaceuticals, cosmetics, or any industry where product quality matters, understanding what a stability chamber does is essential. These specialized units aren’t just fancy boxes—they’re the backbone of accurate environmental testing that predicts how your products hold up over time. From controlling temperature and humidity to meeting strict ICH stability guidelines, stability chambers provide the trusted data you need to ensure safety, efficacy, and compliance. Ready to discover how these chambers give your product the ultimate advantage? Let’s get into it.

What Is a Stability Chamber The Basics Explained

A stability chamber is a specialized controlled environment designed to simulate specific temperature, humidity, and light conditions. Its primary role is to monitor how products degrade over time under these controlled settings. By creating a stable atmosphere, it helps manufacturers understand a product’s shelf life, potency, and overall durability.

Historically, stability chambers evolved alongside global regulatory guidelines, especially the ICH (International Council for Harmonisation) standards Q1A through Q1F. These guidelines standardized testing conditions worldwide to ensure consistency and reliability in stability testing across industries.

What sets stability chambers apart from general environmental chambers is their focus on long-term product stability testing rather than just short-term stress conditions. While environmental chambers might be used for quick stress tests, stability chambers provide precise conditions to evaluate product quality over weeks or months, making them essential for compliance with pharmaceutical shelf life testing and other regulatory demands.

How Does a Stability Chamber Work Inside the Science

A stability chamber works by carefully controlling temperature, humidity, and sometimes light to mimic real-world conditions products face over time. The basic principle is managing thermodynamics—keeping temperature steady helps maintain consistent relative humidity (RH). Sensors and thermostats work together to monitor and adjust the environment, ensuring accuracy.

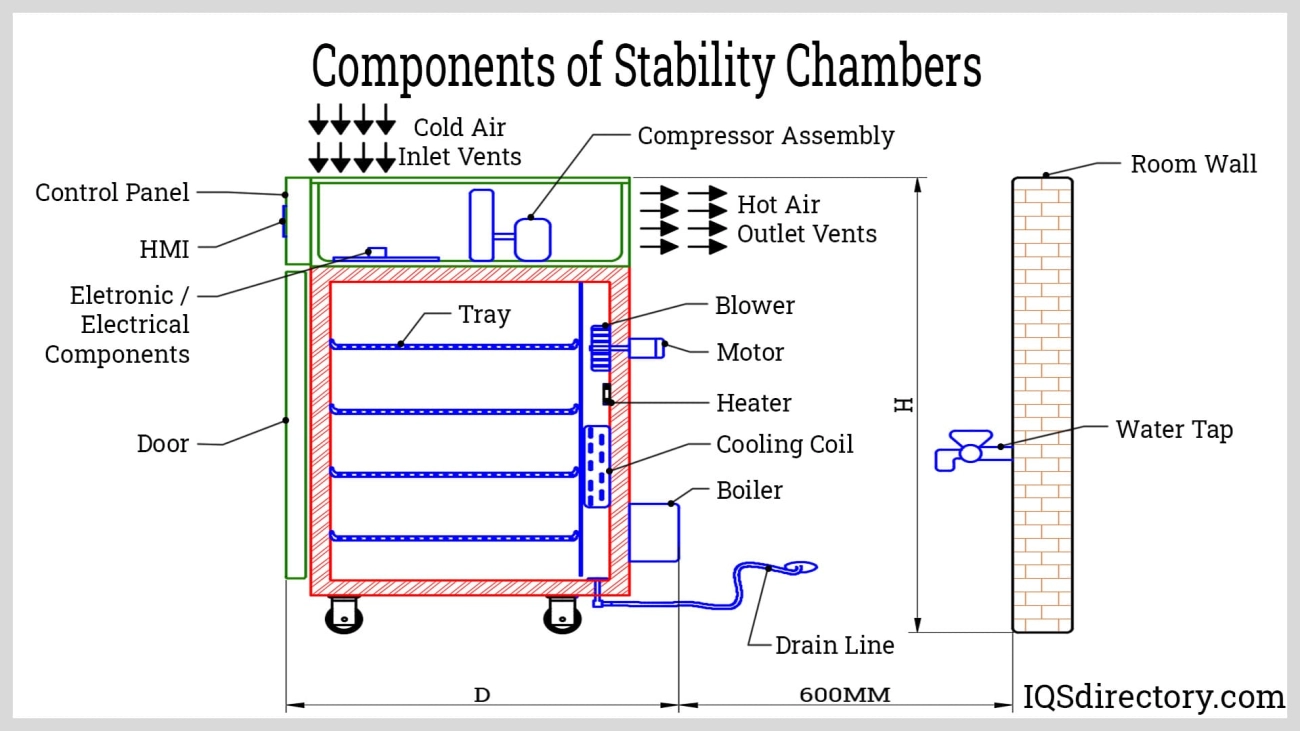

Core Components

- Heating and cooling units: Control temperature precisely within set ranges.

- Humidifiers and dehumidifiers: Keep moisture levels stable.

- Sensors and data loggers: Track temperature and humidity continuously, logging data for analysis.

- Safety features and alarms: Alert users if conditions drift outside preset limits.

Step-by-Step Process

- Setup: Load samples and configure required temp and RH settings.

- Conditioning: The chamber stabilizes the environment before testing begins.

- Monitoring: Continuous tracking through built-in sensors records any fluctuations.

- Data extraction: Logged information is retrieved for degradation or shelf-life analysis.

Typical Specs Table

| Parameter | Typical Range | Notes |

|---|---|---|

| Temperature | 15°C to 60°C | ±0.5°C uniformity |

| Relative Humidity | 40% to 98% | Stable control crucial |

| Uniformity | ±0.5°C | Ensures consistent results |

These specs help ensure stability chambers provide reliable, repeatable environments that meet ICH guidelines and other regulatory standards. This precise control is what separates a stability chamber from a general environmental chamber, focusing on long-term stability testing rather than quick stress tests.

Primary Functions What Does a Stability Chamber Actually Do

A stability chamber’s main job is to simulate real-world environmental stressors like temperature, humidity, and light to see how products hold up over time. For example, running a test at 40°C and 75% RH for six months often equals years of shelf life data. This accelerated aging helps predict how long a product stays effective without waiting for real time.

These chambers also ensure your products meet regulatory requirements. They’re designed to cover ICH stability zones I through IV, so your testing aligns with global standards. Photostability testing is another key function, exposing products to controlled light levels to check for degradation.

Thanks to real-time monitoring, stability chambers provide valuable data on potency loss, shelf life, and formulation tweaks needed to improve product durability. In the pharmaceutical world, this means testing drug efficacy under EMA and FDA-mandated conditions, helping companies meet strict compliance while optimizing product quality.

Types of Stability Chambers Choosing the Right Fit for Your Needs

When choosing a stability chamber, it’s important to pick the right type based on your testing needs, sample size, and environment. Here’s a quick guide to help you decide.

Reach-in vs Walk-in Chambers

- Reach-in Chambers

- Ideal for lab-scale testing

- Perfect for small batches or samples

- Compact size saves lab space

- Walk-in Chambers

- Designed for large-batch testing

- Suitable for bigger products or bulk samples

- Offers more room but takes up more floor space

Specialized Stability Chamber Variants

- Photostability Chambers

- Test product exposure to UV and white light

- Important for drugs and cosmetics sensitive to light

- Refrigerated Chambers

- Maintain low temperatures for cold-chain products

- Essential for biologics and vaccines

- High Humidity Chambers

- Handle up to 98% RH for moisture-sensitive items

How to Choose the Right Stability Chamber

Look at these factors when selecting a chamber:

| Factor | What to Consider |

|---|---|

| Size & Capacity | Match chamber size to your sample quantity |

| Energy Efficiency | Lower running costs with efficient systems |

| Load Capacity | Can it handle heat generated by your samples? |

| Environmental Range | Temperature and humidity limits needed |

| Specialized Needs | Exposure to light, refrigeration, or high RH |

Dexiang Model Recommendations

| Chamber Type | Capacity | Ideal For | Dexiang Model |

|---|---|---|---|

| Reach-in | Small samples | Lab research & QA | Dexiang RX-50 |

| Walk-in | Large batches | Production scale testing | Dexiang WX-200 |

| Photostability | Varies | Light exposure testing | Dexiang PS-100 |

| Refrigerated | Varies | Cold storage for biologics | Dexiang RF-80 |

Picking the right stability chamber ensures reliable testing while optimizing space and energy use. For tailored recommendations, Dexiang offers expert consultation based on your specific needs.

Applications Across Industries Real-World Impact

Stability chambers play a crucial role across many industries by helping businesses understand how products hold up over time under different conditions.

Pharmaceuticals and Biotech

These chambers are essential for testing the shelf life of active pharmaceutical ingredients (APIs) and drug formulations. This helps ensure efficacy and safety throughout the product’s lifespan, keeping you compliant with FDA and EMA guidelines.

Food and Beverages

Stability chambers simulate various climates to predict spoilage and extend shelf life. This is key for products that move through different environments before reaching your shelves, reducing waste and ensuring quality.

Cosmetics and Electronics

For cosmetics, stability chambers test how humidity and light affect product integrity and packaging. In electronics, they help confirm that components can handle environmental stresses without failure, ensuring durability and customer satisfaction.

Real-World Example

A Dexiang client in the pharmaceutical sector used our stability chambers to extend their product viability by 20%. This not only improved shelf life but also boosted market confidence.

Industry Benefits

- Cuts recall risks by up to 30% through early detection of potential stability issues

- Supports compliance across ICH stability guidelines

- Provides actionable, data-driven insights to tweak formulations and packaging before launch

By relying on stability testing equipment like Dexiang’s chambers, companies across these sectors can save costs, improve product quality, and stay ahead in competitive markets.

Key Benefits and Challenges Maximizing ROI

Using a stability chamber brings clear benefits, but it’s not without some challenges. Knowing what to expect will help you get the most value for your investment.

Benefits

- Precision and ComplianceStability chambers ensure accurate temperature and humidity control, fully meeting ICH stability guidelines. This precision supports reliable shelf life studies and regulatory approvals.

- Cost Savings Compared to Field TrialsInstead of waiting months or years in real-time conditions, accelerated stability testing helps you get results faster with less expense.

- Scalability for R&DFrom small lab samples to larger batches, stability chambers adapt well to R&D needs, making product development smoother and more predictable.

Challenges

- Initial InvestmentHigh upfront costs for equipment might be a hurdle for smaller operations.

- Validation NeedsTo meet FDA and EMA standards, ongoing validation like IQ, OQ, PQ processes is essential to prove accuracy.

- Maintenance and CalibrationRegular upkeep is a must. Calibration every 6 months keeps the chamber performing reliably and maintains compliance.

Solutions from Dexiang

Dexiang’s stability chambers address these challenges with:

- Energy-Efficient DesignsSave on operational costs without sacrificing performance.

- Validation ServicesWe help you stay audit-ready with pre-validated chambers and support for your compliance documentation.

Quick Pros and Cons with Tips

| Pros | Cons | Mitigation Tips |

|---|---|---|

| Accurate ICH-compliant data | High upfront cost | Consider leasing options or phased purchase |

| Faster product development | Requires ongoing calibration | Schedule calibration with maintenance |

| Scalable for different batch sizes | Needs skilled operators | Train staff thoroughly, use Dexiang support |

Understanding these pros and cons helps you maximize ROI and keeps your stability testing on track. Reach out to Dexiang for tailored solutions that fit your needs.

ICH Guidelines and Compliance Navigating Standards

When it comes to stability testing equipment, following ICH guidelines is critical for success in the U.S. and global markets. The ICH Q1A(R2) guideline sets the standard for stability testing of new drugs. It defines specific conditions like Zone II, which is 25°C and 60% relative humidity (RH), commonly used for shelf-life testing.

Validation Essentials

To meet regulatory requirements from the FDA and EMA, your stability chamber must pass thorough validation, including:

- Installation Qualification (IQ): Ensures the chamber is installed correctly.

- Operational Qualification (OQ): Verifies the chamber operates within set parameters.

- Performance Qualification (PQ): Confirms consistent performance during actual testing.

Critical limits for temperature and humidity deviations are typically:

- Temperature ±2°C

- Relative Humidity ±5%

Keeping conditions tightly controlled ensures your test results are accurate and compliant.

Dexiang’s Edge

At Dexiang, we offer pre-validated stability chambers built specifically to meet these stringent ICH guidelines. This means less hassle for your team during FDA and EMA audits, providing peace of mind that your stability testing equipment is ready to deliver reliable, compliant data.

Compliance Roadmap Checklist

To keep your stability chamber compliant and audit-ready, follow these five key steps:

- Select a chamber designed for ICH guideline compliance.

- Complete IQ, OQ, and PQ validation.

- Maintain calibration with regular checks every 6 months.

- Monitor and log temperature and humidity continuously.

- Document deviations and corrective actions promptly.

Following this roadmap helps keep your stability testing on track, reducing delays and costly compliance issues. For U.S. customers focused on pharmaceutical shelf life testing, partnering with Dexiang means trusted support every step of the way.

Selecting and Maintaining Your Stability Chamber Expert Tips

Choosing the right stability chamber is key to getting accurate, reliable results. Here are a few simple tips to help you pick and maintain the best unit for your needs.

Buying Guide

- Assess Your Needs: Know the size and type of your device under test (DUT). Will you test small batches or larger volumes?

- Ramp Rates: Consider how quickly the chamber can reach and stabilize at target temperature and humidity levels. Fast ramp rates save time but can stress samples if too abrupt.

- Customization Options: Dexiang offers tailored solutions for specific testing requirements—ask about custom programming, data logging, and control features to fit your workflow.

Maintenance Best Practices

- Regular Cleaning: Keep the interior free of dust, spills, or mold to avoid contamination and sensor interference.

- Sensor Calibration: Schedule sensor checks at least every six months to ensure temperature and humidity readings stay accurate.

- Software Updates: Stay current with any firmware or software updates that improve control systems or data accuracy.

Common Pitfalls to Avoid

- Undersizing Chamber: Don’t underestimate space needs. Overloading or tightly packing can impact uniform temperature and humidity distribution.

- Ignoring Live-Load Effects: Remember that samples themselves can generate heat or moisture. Choose chambers that handle these variations for precise control.

For expert advice and customized chamber solutions designed for the U.S. pharmaceutical and biotech markets, contact Dexiang today for a free consultation. We’ll help you get the stability chamber that fits your goals perfectly. When it comes to environmental test chambers, our manufacturer is a leading provider in the industry. We offer a wide range of high-quality products that are designed to meet the diverse needs of our customers. Our environmental test chambers are used in various applications, including aerospace, automotive, electronics, and more.

deruitest|chambe

我们是专业的WordPress网站建设团队,提供高品质的WordPress主题。新主题微信公众号:cntestingchamber.com,欢迎热爱WordPress的每一位朋友关注!

相关推荐

- How Many Types of Stability Chambers Are There Explained with Features

- What Is the Purpose of the Aging Test Explained for Manufacturers

- What is the 85 85 Damp Heat Test Guide for Reliable Product Testing

- Incubator vs Environmental Chamber Differences Features and Uses Explained

- What Is an Environmental Test Chamber How It Works and Key Features

© 2025. All Rights Reserved. cntestingchamber.com Theme By XinTheme