- Welcome to, We are a professional factory specializing in the production of testing chamber equipment.

- WhatsApp:+8615112812380

站内搜索

菜单演示

相关推荐

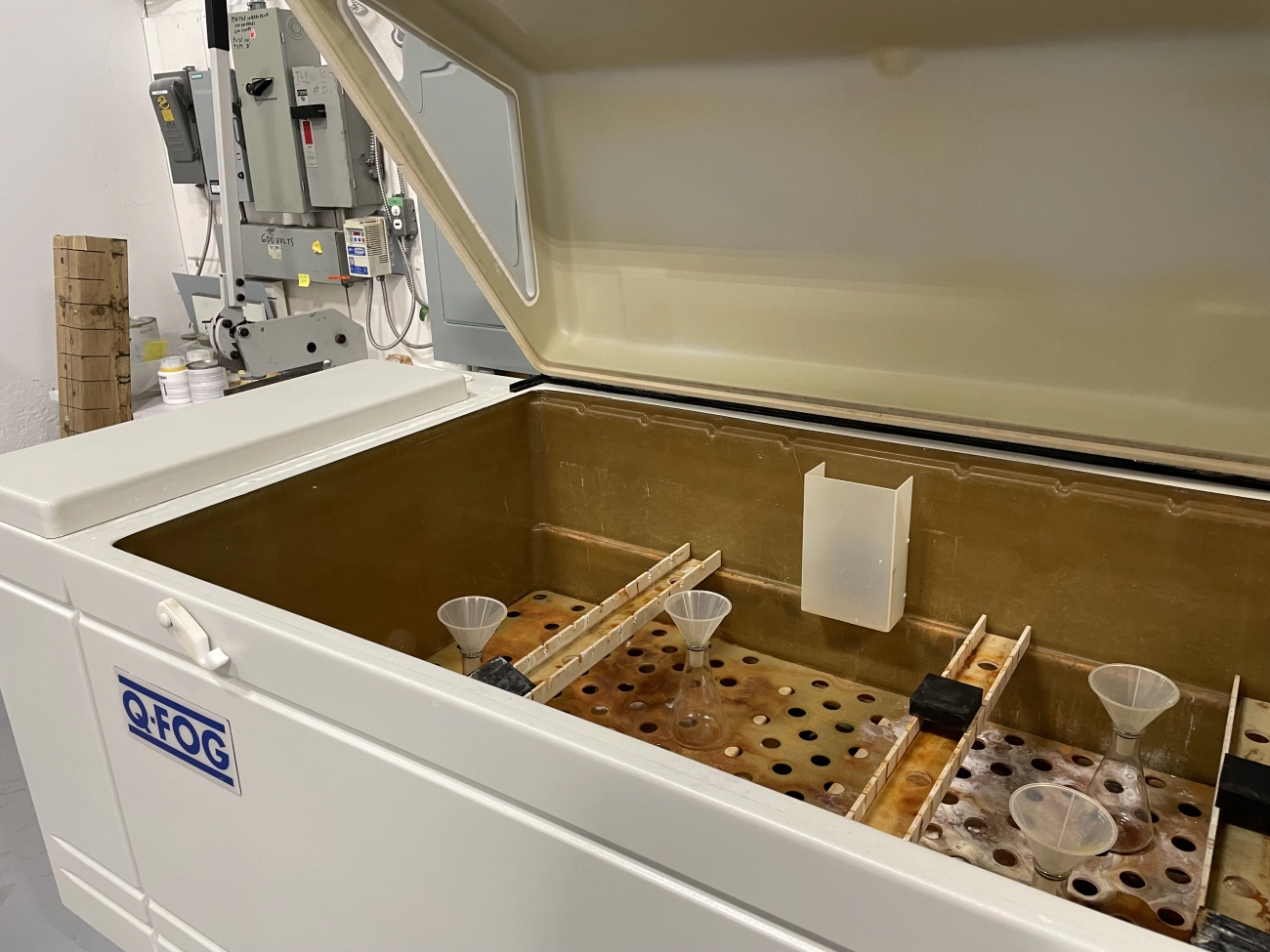

Fundamentals of Salt Spray Testing

Salt spray testing is a widely used accelerated corrosion test designed to simulate the effects of a saline environment on metals and coatings. The core principle involves exposing samples to a neutral salt fog—typically a 5% sodium chloride (NaCl) solution—under controlled temperature and humidity. This environment mimics coastal or marine conditions, allowing manufacturers to assess corrosion resistance quickly and efficiently.

Key Standards to Know

Two major standards guide salt spray testing:

- ASTM B117: The most commonly used method in the U.S., it specifies neutral salt spray (NSS) conditions with a controlled pH around 6.5–7.2, solution concentration, temperature (usually 35°C), and fog rate. ASTM B117 is straightforward and widely recognized for coating failure analysis.

- ISO 9227: An international counterpart offering similar test parameters but also includes variants like acetic acid salt spray (AASS) and cyclic corrosion tests. ISO standards often emphasize repeatability and expanded test conditions.

Neutral Salt Spray vs Cyclic Tests

- NSS tests keep samples constantly exposed to a neutral salt fog, ideal for basic corrosion resistance evaluation.

- Cyclic salt spray tests alternate between salt fog exposure and drying or humidity phases, better replicating real-world environmental cycles. These are more complex but provide a closer match to actual field conditions.

Importance of Test Duration

Test duration, often expressed in hours, is crucial but should not be taken at face value:

- Hours to failure: This is the time until visible corrosion or coating breakdown occurs. It’s a key metric but varies widely based on coating type, preparation, and test conditions.

- Longer exposure doesn’t always mean better data. Some coatings may degrade after extended cycles not seen in shorter tests.

Precision and Reproducibility

Modern salt spray test chambers are engineered for stability and repeatable results:

- They maintain strict control over temperature, salt fog concentration, and pH.

- High-quality chambers reduce variability, allowing consistent comparisons across batches and labs.

- Precise calibration and environmental monitoring are vital for trustworthy data.

Understanding these fundamentals sets the stage for interpreting salt spray test results accurately, ensuring you get meaningful insights into corrosion resistance and coating durability.

Step-by-Step Process Conducting a Salt Spray Test

To get reliable salt spray corrosion resistance results, the testing process must be precise from start to finish. Here’s a simple breakdown of the key steps:

Sample Preparation

- Cleaning: Remove grease, dirt, and any contaminants. Use solvents or mild detergents to ensure the surface is ready for testing.

- Coating: Apply your paint, plating, or protective layer evenly. Make sure coatings are cured properly before the test starts.

Execution Parameters

- Temperature: Keep the chamber around 95°F (35°C) for most neutral salt spray tests like ASTM B117.

- pH Level: Maintain the salt solution pH between 6.5 and 7.2. This ensures a neutral salt fog, avoiding overly harsh acidic or alkaline conditions.

- Fog Rate: Control the salt fog fogging rate to create consistent and fine mist exposure without flooding the samples.

Post-Test Handling

- Rinsing: Some standards require rinsing after testing to remove salt residues gently. Follow your protocol carefully.

- Drying: Let samples dry at room temperature; avoid rapid or forced drying as it could alter corrosion appearance.

- Initial Inspection: Check immediately for visible corrosion, blistering, or coating damage. Document findings before further tests.

Calibration and Maintenance

- Regularly calibrate your salt spray test chambers for temperature, pH, and fog rate.

- Clean nozzles and reservoirs to prevent salt buildup and inconsistent fog.

- Schedule maintenance and performance audits to keep your corrosion testing accurate and reproducible.

Following these clear steps ensures your neutral salt spray test results are trustworthy, helping you evaluate coating failure and corrosion resistance effectively.

Key Metrics and Visual Indicators What to Look For in Salt Spray Results

When interpreting salt spray corrosion resistance results, it’s important to focus on both quantitative metrics and qualitative visuals to get a full picture of how your coating or material performed.

Quantitative Metrics

- Time to First Corrosion: This tells you how long it took before any corrosion signs appeared. It’s a crucial indicator of coating durability.

- Corrosion Spread: Measured as the percentage or area affected, this shows how fast corrosion is growing after it starts.

- Rating Systems: Many labs use corrosion rating scales based on standards like ASTM B117 to grade severity. These help compare samples easily.

- Blistering Assessments: Look for blister size, density, and distribution, as blisters can signal coating failure under stress.

Qualitative Visuals

- Uniform Corrosion: Indicates how evenly the salt spray affects the surface. Uniform rust or discoloration might mean consistent exposure or a coating flaw.

- Pitting and Crevice Corrosion: These localized attacks reveal weaknesses in the coating or substrate, often pointing to small defects or edges.

- Oxide Formation Stages: Visualizing early-stage rust versus advanced oxidation helps understand how corrosion progresses over time.

Tools for Evaluation

- Use magnifying lenses or microscopes for detailed inspection of tiny pits or blisters.

- Digital imaging with high-resolution cameras allows for documentation and easier comparison between test batches.

- Software tools can assist in quantifying corrosion spread and blister counts for more objective results.

Keeping an eye on both the numbers and visuals gives you a reliable way to interpret neutral salt spray test results and make informed decisions about coating performance and improvements.

Interpreting Salt Spray Test Results Pass Fail Criteria and Real World Correlation

When it comes to interpreting salt spray corrosion resistance results, the first step is understanding the pass/fail criteria set by your relevant benchmarks or specifications. These often come from industry standards like ASTM B117 or customer requirements, which define acceptable levels of corrosion, blistering, or coating failure after a certain number of test hours. Make sure your results align with these limits to determine compliance.

Comparing Batches and Coating Types

It’s important to compare test outcomes across different batches and coating types. Small variations in formulations or application methods can impact corrosion resistance significantly. Tracking this data helps identify consistent quality or flag problem areas early — something especially critical in industries like automotive and marine hardware, where corrosion can compromise safety and durability.

Lab Results vs Real World Performance

Keep in mind, salt spray tests provide accelerated corrosion data under controlled conditions, but they don’t always directly predict field life. Real-world environments involve factors like UV exposure, temperature changes, and mechanical wear that salt fog alone can’t replicate. Use test results as a guideline rather than a guaranteed lifespan indicator.

Case Study on Marine Hardware

For example, in marine hardware, salt spray testing revealed early coating breakdown on a batch of fasteners. Based on these results, the coating formulation was adjusted to enhance barrier properties and reduce pitting. Follow-up tests confirmed improved corrosion resistance, aligning better with actual sea use. This shows how interpreting results correctly can guide effective coating improvements tailored for tough environments.

By focusing on these points, you can use salt spray test results more effectively for quality control, product development, and ensuring your coatings meet real-world demands here in the United States.

Common Pitfalls in Interpretation and How to Avoid Them

When interpreting salt spray test results, it’s easy to slip up if you just look at the number of hours without considering the bigger picture. Hours alone don’t tell the full story—context matters. For example, edge effects (corrosion starting at sample edges) can make a coating look worse than it is. Always watch for areas where corrosion begins that aren’t typical of the rest of your sample.

Environmental factors can also throw off your results. pH drift inside the salt spray chamber or excessive salt fog buildup (over-collection) can accelerate corrosion unnaturally. These variables might make your test less reliable for real-world conditions. That’s why regular chamber audits are crucial to keep the environment consistent and within standards like ASTM B117 or ISO 9227.

To avoid these pitfalls, follow these best practices:

- Run tests on multiple samples to rule out anomalies

- Cross-check salt spray results with other corrosion evaluation methods, like cyclic corrosion or electrochemical tests

- Maintain your test chamber frequently with proper calibration and cleaning

- Use automated monitoring systems when possible to track conditions precisely and catch issues early

Taking these steps helps you get clearer, more dependable salt spray corrosion resistance data. It also protects you from common errors that lead to misinterpretation or overestimation of coating failure. As a trusted salt spray test machine manufacturer here in the US, we recommend strict adherence to these practices for meaningful and reproducible results.

Advanced Applications Leveraging Salt Spray Insights for Innovation

Salt spray testing isn’t just about detecting corrosion; it’s a stepping stone to smarter, more innovative solutions in industries like automotive and aerospace, where corrosion resistance is critical.

Industry Specific Applications

- Automotive: Helps in selecting coatings that can handle road salt and weather fluctuations, reducing warranty claims.

- Aerospace: Ensures parts can survive harsh salty environments without compromising safety or performance.

Integration with Other Tests

Salt spray results often work hand-in-hand with cyclic corrosion and electrochemical tests. Combining these methods gives a fuller picture of how materials and coatings will perform over time in real-world conditions.

Emerging Trends

- AI Result Prediction: Artificial intelligence is starting to analyze salt spray data to predict coating failures faster and more accurately.

- Eco-Friendly Testing: Newer test chambers focus on reducing waste and energy while still delivering trusted accelerated corrosion results.

Consultation and Custom Chamber Benefits

As an experienced environmental test chamber manufacturer, our capabilities include designing and supplying precision salt spray test machines. We offer expert consultation to tailor these setups to your specific U.S. requirements, with custom chambers that provide exact control over temperature and fog rates for guaranteed reproducibility and reliable data.

Using insights from salt spray testing with these advanced approaches can help your products last longer and perform better in the toughest environments.

deruitest|chambe

我们是专业的WordPress网站建设团队,提供高品质的WordPress主题。新主题微信公众号:cntestingchamber.com,欢迎热爱WordPress的每一位朋友关注!

相关推荐

- How Many Types of Stability Chambers Are There Explained with Features

- What Is the Purpose of the Aging Test Explained for Manufacturers

- What is the 85 85 Damp Heat Test Guide for Reliable Product Testing

- Incubator vs Environmental Chamber Differences Features and Uses Explained

- What Is an Environmental Test Chamber How It Works and Key Features

© 2025. All Rights Reserved. cntestingchamber.com Theme By XinTheme