-

Dexiang: Delivering Trust. Your Reliable Environmental Test Chamber Manufacturer.

- WhatsApp:+8615112812380

NSS Test Chamber vs CASS & AASS: How to Choose the Right Corrosion Test

- Category: Salt Spray Test Chamber

- |

- Date: 04/07/2020 11:57

The NSS Test Chamber simulates salt fog corrosion to evaluate material durability. Complying with ASTM B117/ISO 9227, it provides accelerated corrosion resistance testing for automotive, aerospace, and metal components.

- Modle : DX-NSS-500-1

- Payment: L/C, D/P, T/T

- Applicable Standards:DIN EN ISO 9227 (NSS, ESS, CASS)

- Temperature Range : Room temperature ~ 55℃

- Temperature Fluctuations : ≤±0.5℃

- Temperature Uniformity :≤±2℃

Product Details

What is an NSS Test Chamber and Why Do You Need One

An NSS Test Chamber, also known as a Neutral Salt Spray Tester or Salt Fog Corrosion Chamber, is a device designed to simulate corrosive environments. It sprays a fine mist of salt solution to accelerate the corrosion process on metal samples, coatings, and materials. This test is essential for evaluating corrosion resistance quickly and reliably.

Understanding Neutral Salt Spray NSS Testing Basics

- Test Type: Neutral salt spray (NSS) exposes materials to a salt fog with a pH around 6.5 to 7.2.

- Purpose: It replicates natural corrosion effects in a controlled, accelerated way.

- Standards: Commonly follows ASTM B117 and ISO 9227 standards.

- Test Duration: Varies from hours to days depending on product requirements.

Key Applications in High-Stakes Industries

NSS testing is vital across industries where corrosion can cause failure, costs, or safety issues:

| Industry | Common Use Cases |

|---|---|

| Automotive | Testing paint, coatings, and parts |

| Aerospace | Validating components for durability |

| Marine | Evaluating metal resistance to salt |

| Electronics | Ensuring enclosures withstand corrosion |

| Construction | Testing steel and coatings reliability |

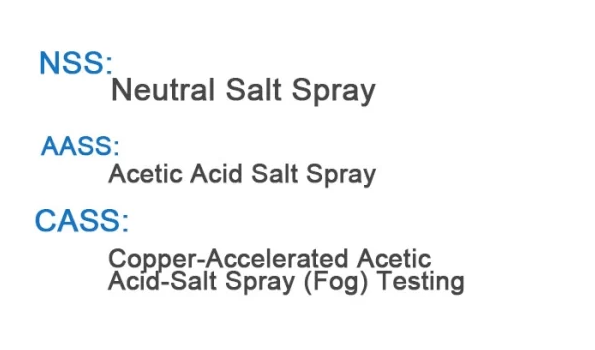

NSS vs AASS and CASS When to Choose Neutral Testing

Different salt spray tests use varied solutions and pH levels:

| Test Type | Solution Type | pH Range | Application Scenario |

|---|---|---|---|

| NSS Test Chamber | Neutral Sodium Chloride | 6.5–7.2 | General corrosion resistance testing |

| AASS | Acidic Acetic Acid Salt Spray | ~3.0 | Testing higher corrosion scenarios with acids |

| CASS | Copper Accelerated Salt Spray | ~3.0 | Coating durability under acidic, copper-rich fog |

Choose NSS testing when:

- You need a reliable baseline corrosion resistance check.

- The test mimics neutral natural environments.

- Compliance with ASTM B117 or ISO 9227 is required.

In short, an NSS Test Chamber is your go-to choice for fast, standardized, and relevant corrosion resistance testing. It ensures your products meet industry quality demands and perform safely in the field.

Why Choose Dexiang’s NSS Test Chamber for Superior Results

When it comes to corrosion testing, Dexiang’s NSS Test Chamber stands out for delivering reliable, precise results every time. Here’s why it’s a smart choice for your lab or production line:As a committed environmental test chamber manufacturer, we engineer each product to solve real-world testing challenges with precision and durability.

Advanced Features for Precision and Efficiency

- Accurate Environment Control: Maintains stable temperature and humidity for consistent test results.

- User-Friendly Interface: Easy programming with touchscreen control, so you can set and monitor tests without hassle.

- Automated Salt Spray Delivery: Ensures uniform salt fog distribution for reliable and repeatable corrosion testing.

- Quick Test Cycles: Reduces testing time without compromising accuracy.

Built for Durability Materials and Safety Standards

- Corrosion-Resistant Construction: Made from high-grade stainless steel to handle harsh salt spray environments.

- Safety First: Equipped with fail-safe sensors and alarms to protect both the equipment and users.

- Robust Sealing: Prevents leaks and contamination, ensuring your testing environment stays clean and controlled.

Proven Compliance with Global Standards

| Standard | Dexiang NSS Test Chamber Compliance |

|---|---|

| ASTM B117 | Fully meets requirements for salt spray testing |

| ISO 9227 | Certified to carry out Neutral Salt Spray Tests |

| CASS Testing | Compatible with copper-accelerated salt spray (Acetic Acid Salt Spray) |

Choosing Dexiang means you’re not only investing in a machine but reliable corrosion test data recognized across key US industries like automotive, aerospace, and manufacturing.

Detailed Technical Specifications of the Dexiang NSS Test Chamber

The Dexiang NSS Test Chamber is built with precision and reliability in mind, offering features that meet strict corrosion testing needs. Here’s a quick look at the key specs:

| Specification | Details |

|---|---|

| Model | Dexiang NSS-500 |

| Chamber Size | 500 x 500 x 500 mm |

| Test Method | Neutral Salt Spray (ISO 9227) |

| Spray Control | Automated, adjustable spray rate |

| Temperature Range | 35°C to 50°C |

| Display | Digital control panel with LCD |

| Construction Material | High-quality stainless steel |

| Test Duration | Adjustable, from hours up to 1000 hrs |

| Power Supply | 220V/110V compatible |

| Water Supply | Deionized water recommended |

| Safety Features | Overheat protection, leak-proof |

| Compliance | ASTM B117, ISO 9227 |

This chamber is designed to provide consistent and accurate salt fog conditions for testing the corrosion resistance of coatings and materials.

Customization Options for Your Workflow

We understand every lab and testing process is different. Dexiang offers flexible customization to fit your specific needs:

- Size Variations: Choose a chamber size that suits your sample requirements.

- Test Programs: Custom programming options for various test durations and intervals.

- Spray Control: Adjustable salt concentration levels and fog density settings.

- Data Logging: Integration with digital data recorders to track test conditions in real-time.

- Multi-Chamber Systems: Options for combining multiple chambers to increase testing capacity.

- Safety Add-ons: Optional alarms, ventilation, and enhanced filtration systems.

No matter your workflow size or complexity, Dexiang’s NSS Test Chamber can be tailored to fit smoothly into your corrosion testing routine.

Step-by-Step Guide How to Conduct NSS Testing with Dexiang

Conducting Neutral Salt Spray (NSS) testing with Dexiang’s NSS Test Chamber is straightforward and built for reliable results. Here’s a simple step-by-step process to follow:

- Prepare Your SamplesClean and dry the materials or coatings you want to test. Make sure they’re free from dirt or oils that might affect results.

- Set Up the Dexiang NSS Test ChamberFill the chamber’s salt solution tank with the recommended saline mix (usually 5% sodium chloride). Ensure the chamber is sealed properly.

- Load Your SamplesPlace your samples inside on the designated rack, making sure they don’t touch each other or the sides.

- Program Test ParametersUse the chamber’s easy interface to set temperature, spray rate, and duration based on your testing requirements or relevant standards like ASTM B117 or ISO 9227.

- Start the TestTurn on the chamber to begin the salt fog exposure. The Dexiang system controls the environment tightly to simulate long-term corrosion effects fast.

- Monitor ProgressKeep an eye on humidity, temperature, and solution levels. Dexiang chambers come with built-in alerts to help you maintain proper conditions.

- End Testing and Inspect SamplesAfter the set time, stop the test, carefully remove samples, rinse if required, and inspect them for coating degradation, rust, or other corrosion signs.

Common Challenges and Dexiang Solutions

NSS testing can come with a few hurdles, but Dexiang’s design handles these smoothly:

- Maintaining Test ConsistencyProblem: Fluctuations in temperature or spray can skew results

Solution: Dexiang’s precise control system ensures stable conditions every cycle. - Salt Solution ContaminationProblem: Impurities can affect spray quality and accuracy

Solution: Easy cleaning and refill protocols with high-quality materials prevent contamination. - Sample Positioning IssuesProblem: Uneven exposure if samples aren’t placed correctly

Solution: Clear loading guides and racks in the chamber help users position samples evenly. - Durability of the Chamber ItselfProblem: Corrosion inside the chamber over long-term use

Solution: Dexiang uses corrosion-resistant materials inside the chamber to extend lifespan and reduce maintenance.

Using Dexiang’s NSS Test Chamber helps you overcome common testing headaches, providing reliable, repeatable corrosion resistance testing for your products.

Real-World Success Stories and Industry Insights

Many local U.S. businesses have turned to Dexiang’s NSS Test Chamber to boost their corrosion testing accuracy and efficiency. Manufacturers in automotive, aerospace, and metal fabrication industries report better quality control and faster product development times thanks to reliable neutral salt spray testing. For example, a Midwest aerospace supplier cut their failure rates by 30% after switching to Dexiang’s salt fog corrosion chamber, helping them meet strict FAA standards with ease.

Looking ahead, corrosion testing is evolving with smarter, more adaptable NSS technology. Trends like integrating digital monitoring, AI-assisted data analysis, and enhanced environmental controls are making neutral salt spray testers more precise and user-friendly. These advances mean faster insights, less downtime, and improved coating durability tests that align well with the growing demands of U.S. manufacturers focused on sustainability and long-lasting product life.

With Dexiang’s continued commitment to innovation and compliance with ASTM B117 and ISO 9227 standards, customers are well-positioned to stay ahead in corrosion resistance testing. Whether it’s local case studies proving success or the latest NSS tech trends, Dexiang remains a trusted partner in protecting U.S. products from corrosion damage.

Frequently Asked Questions FAQ

What is an NSS Test Chamber used for?

An NSS Test Chamber is designed to simulate salty, corrosive environments to evaluate how materials and coatings hold up over time. It helps predict the durability of your products against rust and corrosion.

How does NSS testing differ from CASS or AASS testing?

NSS testing uses neutral salt spray, which is less harsh and focuses on general corrosion resistance. CASS and AASS involve acidic components that accelerate corrosion faster, ideal for more aggressive environments.

Which industries benefit most from using an NSS Test Chamber?

Automotive, aerospace, electronics, and metal fabrication industries frequently rely on NSS testing to ensure their components withstand salty or coastal environments.

What standards does Dexiang’s NSS Test Chamber meet?

Our chambers comply with ASTM B117 and ISO 9227 standards, aligning with global requirements for salt spray corrosion testing.

Can I customize the Dexiang NSS Test Chamber for my specific needs?

Yes. We offer customization options for size, materials, and automated features to fit your unique testing workflow.

How often should I perform NSS testing?

Testing frequency depends on your product’s lifecycle and exposure conditions, but typically once during development and periodically during quality control.

Is the Dexiang NSS Test Chamber safe and easy to operate?

Absolutely. It’s designed with user safety in mind, using durable materials and clear controls that make testing straightforward for operators.

Does Dexiang offer support if I face challenges during NSS testing?

Yes, we provide expert support and troubleshooting services to help resolve common issues you might encounter during testing.

How do I get started with NSS testing using Dexiang equipment?

We provide a simple, step-by-step guide to walk you through setup, operation, and result interpretation to ensure smooth testing from day one.

What makes Dexiang’s NSS Test Chamber a smart choice for US buyers?

Our testing chambers combine advanced features, compliance with US and global standards, and adaptability to US industry demands, ensuring reliable, precise results every time.

Ready to Upgrade Your Corrosion Testing Contact Dexiang Today

If you’re ready to take your corrosion testing to the next level, Dexiang’s NSS Test Chamber is the smart choice. We provide reliable, precise, and easy-to-use Neutral Salt Spray testers built to meet the needs of U.S. industries—from automotive to aerospace and beyond. Our salt fog corrosion chambers are designed for durability and compliance with ASTM B117 and ISO 9227 standards, ensuring your testing stays accurate and consistent.

Get in touch with Dexiang today to discuss how our advanced NSS chambers can fit your workflow, improve your testing efficiency, and deliver trustworthy results every time. Whether you’re upgrading existing equipment or starting fresh, we offer customization and support tailored to your exact needs.

Don’t settle for less in corrosion resistance testing — choose Dexiang for quality, performance, and expert service. Contact us now to learn more and request a quote.

Dexiang| Instruments

As a high-tech manufacturer, we integrate R&D, design, production, and sales under one roof. Our philosophy—"Quality Ensures Survival, Integrity Drives Development, and Management Yields Efficiency"—is woven into every product we build. We continuously assimilate cutting-edge global technologies and refine our practices through years of hands-on experience.

Dexiang Environmental test chamber manufacturer All Rights Reserved.