-

Dexiang: Delivering Trust. Your Reliable Environmental Test Chamber Manufacturer.

- WhatsApp:+8615112812380

If you’re involved in corrosion testing or quality control for metals and coatings, you’ve probably heard about the salt spray test — but what exactly is the ISO standard for salt spray testing? Understanding ISO 9227 is crucial because it sets the global benchmark for simulating corrosive environments and ensuring your materials stand up to real-world challenges. In this quick guide, you’ll get the lowdown on why ISO 9227 matters, how the tests work, and what makes it the go-to standard for industries from automotive to aerospace. Ready to cut through the jargon and get actionable insights on salt spray corrosion testing? Let’s dive in!

What Is the ISO Standard for Salt Spray Testing A Quick Overview

If you’re wondering about the ISO standard for salt spray testing, the answer is ISO 9227. This internationally recognized standard defines the procedure for performing salt spray corrosion tests, commonly known as salt fog tests. These tests simulate a harsh, corrosive environment to evaluate the corrosion resistance of metals, coatings, and surface treatments.

Core Explanation

ISO 9227 outlines how to conduct salt spray corrosion testing using a controlled salt fog chamber. The test involves exposing samples to a fine mist of a saltwater solution, typically sodium chloride, under standardized conditions. This accelerated corrosion simulation helps predict how materials will hold up in real-world environments, saving time compared to natural exposure.

What makes ISO 9227 reliable is its detailed guidance on the test setup, solution composition, temperature, humidity, and duration. It covers different test types that vary based on the corrosive environment you want to mimic—for example, neutral salt spray, acidified salt spray, or copper-accelerated tests.

Historical Context

Developed in the mid-20th century, the salt spray test became popular for rapidly assessing corrosion resistance. ISO standardized these procedures to harmonize testing across industries and countries. Before ISO 9227, many companies relied on ASTM B117, an American standard for salt fog testing, which shares similarities but differs in some key parameters and test methods. ISO 9227 now acts as the go-to standard globally, guiding labs and manufacturers in evaluating protective coatings and metal treatments effectively.

In , ISO 9227 provides a trusted, consistent, and repeatable framework for salt spray corrosion testing, making it an essential reference for product quality and durability assessment worldwide.

Breaking Down the Key Test Methods in ISO 9227

ISO 9227 outlines three main salt spray corrosion testing methods, each designed for different types of corrosion resistance assessments.

Neutral Salt Spray NSS Test

This is the most common and straightforward test. The Neutral Salt Spray (NSS) method sprays a neutral pH saltwater mist (usually sodium chloride) onto the sample. It’s widely used for checking general corrosion resistance of metallic coatings and materials in a simulated salty, humid environment. NSS is great for a baseline corrosion resistance assessment.

Acetic Acid Salt Spray AASS Test

The Acetic Acid Salt Spray (AASS) test adds a bit of acidity by mixing acetic acid with the salt solution. This creates a more aggressive, acidic environment that speeds up corrosion, especially for metals like zinc coatings and galvanized steel. The AASS test better simulates harsher real-world conditions, such as industrial or marine environments where acid rain or pollution might be factors.

Copper Accelerated Acetic Acid Salt Spray CASS Test

The CASS test is the most severe method of the three. It uses acetic acid plus copper chloride, which dramatically accelerates corrosion, especially for metallic coatings like zinc and cadmium. This test helps uncover potential weaknesses in coatings much faster, making it critical for industries needing quick yet thorough corrosion resistance assessments.

Visual Aid Table Comparing NSS, AASS, and CASS

| Test Method | Solution Composition | Corrosion Severity | Typical Use Cases |

|---|---|---|---|

| NSS | Neutral 5% NaCl solution | Mild | General corrosion resistance |

| AASS | 5% NaCl + acetic acid (acidic pH) | Moderate | Acidic or marine-like conditions |

| CASS | 5% NaCl + acetic acid + copper chloride | Severe | Accelerated testing of coatings |

Each method in ISO 9227 serves a specific purpose, letting you tailor corrosion testing to your product’s real-world exposure. Understanding these helps you pick the right method to ensure your materials hold up under different environmental stresses.

Why ISO 9227 Matters Applications and Benefits Across Industries

ISO 9227 is the go-to standard for salt spray corrosion testing in the U.S. and worldwide. It gives manufacturers, engineers, and quality teams a reliable way to check how well metals and coatings hold up against corrosion. The salt spray test simulates harsh environments fast, helping businesses avoid costly failures.

Key Applications

| Industry | Use Case |

|---|---|

| Automotive | Testing paint, coatings, and metal parts for rust resistance |

| Aerospace | Ensuring aircraft components withstand salty, humid conditions |

| Marine | Assessing corrosion resistance on ship parts and equipment |

| Electronics | Checking protective coatings on sensitive devices |

| General Manufacturing | Evaluating metallic coatings and surface treatments |

Each industry depends on ISO 9227 to help predict product lifespan and maintain quality standards, especially where corrosion can cause safety or performance issues.

Benefits of Using ISO 9227

- Consistent Results: Offers a uniform salt spray test procedure, making results reliable and comparable.

- Speed: Accelerates corrosion exposure, so you get clear data in days instead of years.

- Cost Savings: Identifies weaknesses early, reducing warranty claims and repair costs.

- Versatile Testing: Supports multiple testing types like Neutral Salt Spray (NSS) and Copper Accelerated Acetic Acid Salt Spray (CASS), so you can pick based on your product needs.

By following ISO 9227, U.S. companies can ensure their products meet industry-specific corrosion resistance requirements and perform well in real-world conditions.

Step by Step Guide How to Conduct a Salt Spray Test per ISO 9227

Preparation Phase

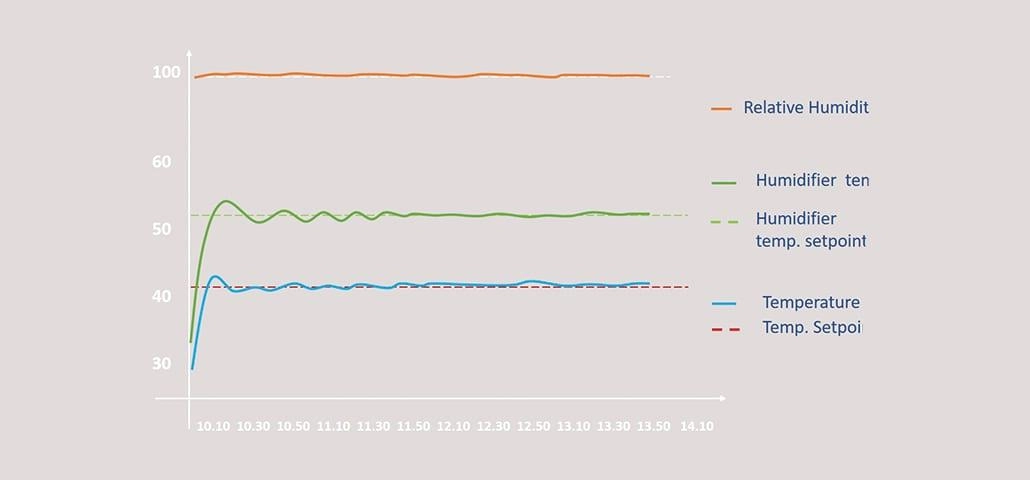

Start by setting up your salt fog chamber properly. Use the right concentration of salt solution—typically a 5% sodium chloride mix for the Neutral Salt Spray (NSS) test. Make sure your samples are clean and free of oils or dirt, as contaminants can affect corrosion results. Calibrate your chamber’s temperature (usually around 35°C) and check that the nozzle sprays evenly. Follow ISO 9227 procedure carefully to ensure consistent and reliable conditions.

Execution Phase

Place your samples inside the chamber at a proper angle to get full exposure to the salt mist. Run the test for the duration specified in your plan—this could range from several hours up to days depending on your testing goals. Keep monitoring the chamber parameters such as temperature, humidity, and salt concentration. Avoid opening the chamber mid-test to maintain stable conditions.

Post Test Evaluation

Once the test finishes, remove the samples and rinse lightly with distilled water to halt further corrosion. Dry them gently and inspect for signs of rust, pitting, or coating failures. Use visual inspection or microscopy if needed to assess corrosion resistance per ISO 9227 standards. Document all findings clearly for accurate evaluation and comparison.

Pro Tip Partner with Dexiang for Turnkey ISO 9227 Testing

If you’re looking to streamline your salt spray corrosion testing, Dexiang offers full-service ISO 9227 testing solutions. They handle everything from chamber setup to reporting, delivering reliable results that meet US industry standards. This can save you time and ensure your testing aligns perfectly with the salt spray test standard.

ISO 9227 vs Other Standards When to Choose What Comparative Analysis

When it comes to salt spray corrosion testing, choosing the right standard matters. ISO 9227 is widely used globally, but other standards like ASTM B117 are common in the U.S. Here’s a quick comparison to help you decide which fits your needs best.

| Feature | ISO 9227 | ASTM B117 | Other Standards (e.g., ASTM G85) |

|---|---|---|---|

| Test Types | NSS, AASS, CASS | Focus on NSS | Specialized accelerated tests (e.g., cyclic, sulfur dioxide) |

| Global Acceptance | Internationally recognized | Mostly U.S. and North America | Varies—often industry-specific |

| Chamber Setup | Standardized salt fog chamber | Similar setup but with slight variations | Custom setups for specialty corrosion simulation |

| Test Duration | Flexible depending on product | Typical fixed durations | Depends on test type |

| Use Case | General corrosion resistance, metallic coatings | General corrosion testing, widely accepted for coatings and metals | Targeted tests for aggressive environments like marine or industrial air |

| Technical Detail | Clear, easy-to-follow procedures | More detailed guidance on procedures | Specialized protocols, sometimes complex |

When to Choose ISO 9227

- You need a globally recognized procedure for metallic coating evaluation.

- Your focus is on neutral salt spray NSS, acetic acid salt spray AASS, or copper accelerated acetic acid salt spray CASS testing.

- You require a standard that fits a wide range of industries like automotive, aerospace, marine, and electronics.

- You want results that align well with international customers and partners.

When to Consider ASTM B117 or Others

- Your business mainly operates within North America and your customers expect ASTM-based results.

- You need to follow accelerated corrosion simulation with more detailed cyclic or aggressive environment protocols.

- Your products require specific testing beyond what ISO 9227 offers, like sulfur dioxide exposure or cyclic corrosion.

Choosing the right salt spray test standard depends on your product requirements, target market, and testing goals. ISO 9227 provides a solid, internationally accepted base for most corrosion resistance assessments, but keep ASTM and other specific standards in mind for specialized cases.

Common Challenges Limitations and Best Practices

Salt spray corrosion testing using the ISO 9227 procedure is great for assessing corrosion resistance, but it’s not without some challenges. Here’s what you should watch out for and how to get the most reliable results.

Pitfalls

- Test Environment Variability: Maintaining consistent temperature and humidity in your salt fog chamber setup can be tricky. Small changes impact corrosion rates and test accuracy.

- Over-Interpretation: Salt spray tests simulate corrosion but don’t exactly mimic real-world conditions. Using results alone to predict long-term performance can be misleading.

- Sample Preparation Errors: Improper cleaning or coating application can affect how corrosion forms during testing, leading to unreliable results.

- Test Duration Mistakes: Running tests too short or too long might cause under- or overestimation of corrosion resistance.

- Misunderstanding Test Types: Confusing Neutral Salt Spray (NSS) with Acidic methods like AASS or Copper Accelerated (CASS) can lead to incorrect test choices.

Best Practices

- Follow ISO 9227 Procedure Closely: Stick to the detailed steps for salt spray corrosion testing, including settings and solution preparation.

- Consistent Chamber Maintenance: Regular calibration and cleaning of the salt fog chamber ensures stable test conditions.

- Choose the Right Test Method: Base your test choice on the actual environment your product will face—NSS for general corrosion, AASS or CASS for harsher acidic conditions.

- Proper Sample Preparation: Make sure samples match real-world coating and surface finishes.

- Combine Tests and Inspections: Use salt spray tests alongside other corrosion resistance assessments and real-world field data.

- Document Everything: Keep detailed records of test conditions, sample details, and outcomes for traceability.

By understanding these common challenges and following best practices, you can make the most out of ISO 9227 salt spray corrosion testing for your products, especially in industries like automotive, marine, and manufacturing where corrosion resistance is key.

As a leading environmental test chamber manufacturer, Dexiang offers free calibration consultations to help global customers optimize their equipment’s performance and extend its lifespan. Our expert support ensures you meet rigorous lab and industrial standards with ease.

Dexiang| Instruments

As a high-tech manufacturer, we integrate R&D, design, production, and sales under one roof. Our philosophy—"Quality Ensures Survival, Integrity Drives Development, and Management Yields Efficiency"—is woven into every product we build. We continuously assimilate cutting-edge global technologies and refine our practices through years of hands-on experience.

Dexiang Environmental test chamber manufacturer All Rights Reserved.