-

Dexiang: Delivering Trust. Your Reliable Environmental Test Chamber Manufacturer.

- WhatsApp:+8615112812380

If you’re working with products that need to withstand tough environments, understanding how to choose between an IPX34 rain test chamber and a dust test chamber is crucial. Whether your product faces heavy rain, splashing water, or dusty, particle-filled conditions, selecting the right test chamber ensures you meet essential IEC 60529 IP ratings and avoid costly failures. In this guide, you’ll discover exactly when to prioritize water ingress testing versus dust protection, helping you make a confident choice that aligns with your product’s real-world challenges and compliance needs. Let’s dive into the key factors that will set your testing strategy up for success.

Understanding IP Ratings: The Foundation for Chamber Selection

Choosing the right test chamber starts with understanding IP ratings—the standardized way to measure a device’s protection against dust and water. The IP code has two digits: the first digit indicates protection against solids like dust, and the second digit shows protection against liquids such as water.

Here’s a quick breakdown:

- First digit (solids/dust protection): Ranges from 0 (no protection) to 6 (dust-tight). For example, IP5X means dust-protected, while IP6X means completely dust-tight.

- Second digit (liquid/water protection): Ranges from 0 to 9, indicating increasing resistance to water intrusion. IPX3 means protection against water spray at 60° angles, and IPX4 provides resistance to water splashing from all directions.

Many products you see come with combined ratings like IP54, IP65, or IP67, meaning they need both dust and water protection tests. For instance, IP54 requires dust protection plus rainfall and splashing resistance, while IP67 guarantees total dust tightness and waterproof immersion.

Because of the different nature of dust and water exposure, manufacturers often use separate chambers for dust and rain tests. This specialization ensures more accurate environmental simulation—rain test chambers focus on spray and splash water, while dust chambers simulate particle ingress using controlled powder circulation and airflow.

Understanding these differences helps you pick the right testing equipment—whether an IPX34 rain test chamber or a dust test chamber—to accurately evaluate your product’s durability under real-world conditions.

What is an IPX34 Rain Test Chamber?

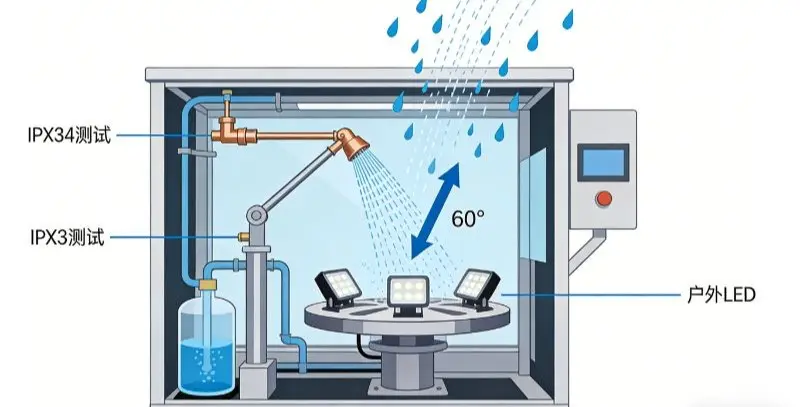

An IPX34 rain test chamber is designed to simulate rain, spray, and splashing water conditions to check how well products hold up against moisture. This chamber uses oscillating tubes or spray nozzles to deliver water at adjustable flow rates, ensuring realistic testing. Many models include a rotating turntable to expose all sides of the product evenly.

The chamber supports IPX3 testing, which sprays water at fixed 60° angles, and IPX4 testing, covering 360° splashing, following key water ingress standards like IEC 60529 and ISO 20653, commonly used in automotive testing.

Typical users include manufacturers of outdoor lighting, automotive parts, and electronic enclosures that need to prove their durability against rain and moisture exposure. If your products require waterproof test equipment to pass IPX3 or IPX4 testing, this chamber is essential.Sourcing it from a specialized environmental test chamber manufacturer guarantees the precision needed for compliance.

What is a Dust Test Chamber?

A dust test chamber is designed to simulate dusty and sandy environments to check how well products resist dust ingress. These chambers help evaluate sealing and protection against tiny particles that can cause damage or reduce performance.

Key features include:

- Circulation of talcum powder or fine dust to mimic real-world conditions

- Controlled airflow to keep dust suspended

- Vacuum systems for stricter tests like IP6X, which require dust-tight environments using negative pressure

Test methods cover:

- IP5X: Ensures products are protected against dust but not completely dust-tight

- IP6X: Confirms a dust-tight seal, preventing any dust from entering under test conditions

These chambers comply with standards like IEC 60529 and military standards such as MIL-STD-810, ensuring reliable and recognized testing methods.

Typical applications for dust test chambers include:

- Military equipment that must perform in harsh desert or dusty environments

- Mining tools exposed to heavy particulate matter

- Devices used in arid or sandy conditions

- Precision electronics that need protection from dust buildup to avoid overheating or failures

Using a dust test chamber is essential for industries where dust ingress protection is a must, helping guarantee product durability and reliability.

Key Differences Between IPX34 Rain Test Chambers and Dust Test Chambers

When choosing between an IPX34 rain test chamber and a dust test chamber, understanding how they differ is crucial. Here’s a quick breakdown:

| Feature | IPX34 Rain Test Chamber | Dust Test Chamber |

|---|---|---|

| Simulation Type | Water spray and splashing (IPX3/IPX4) | Airborne dust particles (IP5X/IP6X) |

| Equipment Design | Nozzle systems, oscillating tubes, water recirculation | Blower fans, talcum powder circulation, vacuum for dust-tight tests |

| Test Duration | Short cycles (minutes to hours) | Prolonged exposure (often 8+ hours) |

| Conditions Simulated | Rain, spray, splashing water | Dust storms, sandy, particulate-heavy environments |

| Main Risks Addressed | Water ingress causing corrosion, short circuits | Dust ingress causing abrasion, overheating, machinery faults |

| Cost & Maintenance | Requires water handling and cleaning; moderate maintenance | Dust clean-up, powder replacement; possibly higher upkeep |

Why These Differences Matter

- Test Purpose: Rain chambers focus on water ingress protection, crucial for electronics or outdoor equipment facing moisture. Dust chambers assess particle sealing to avoid damage from dust buildup.

- Design & Operation: Water systems need precise spray nozzles and flow control, while dust chambers rely on airflow and dust circulation to simulate real conditions.

- Testing Time: Dust tests require longer runs to mimic real-world dust exposure, while rain spray tests are generally quicker.

- Maintenance: Handling water means managing corrosion and drying, whereas dust chambers demand thorough cleaning to avoid contamination.

By knowing these key differences, you can pick the right environmental simulation chamber that matches your product’s testing needs and ensures reliable waterproof or dust-proof testing according to IP ratings.

Factors to Consider When Choosing the Right Chamber

Picking the right test chamber comes down to a few key points that match your product and its environment.

- Product’s Required IP Rating & EnvironmentKnow if your product needs protection against water (IPX3/IPX4) or dust (IP5X/IP6X), based on where it’ll be used. Outdoor gear exposed to rain calls for an IPX34 rain test chamber, while tools used in dusty factories need a dust test chamber.

- Industry-Specific StandardsDifferent industries stick to different rules. Automotive products often follow ISO 20653 for water/dust testing, electronics rely on IEC 60529 compliance, and defense gear may require MIL-STD standards. Make sure your chamber supports the right protocols.

- Testing Volume & Sample SizeConsider how many items you test at once. Smaller benchtop chambers fit limited samples, while walk-in chambers handle larger equipment or batch testing.

- Budget: Standalone vs. Combined ChambersBuying separate rain and dust chambers may cost more upfront but often provide better test precision. Combined IP test chambers save space and money but might sacrifice some test accuracy.

- Compliance NeedsIf your product must meet market certifications like CE or UL, your test equipment must guarantee reliable results for smooth approval.

- Future-ProofingThink ahead—will you need to test for both dust and water soon? Or might you require higher IP levels as product standards evolve? Choosing a flexible chamber now can save headaches later.

Balancing these factors helps you narrow down the best environmental simulation chamber to protect your product’s quality and market success.

When to Choose an IPX34 Rain Test Chamber

If your products face rain, humidity, or water splashes, an IPX34 rain test chamber is a smart choice. This chamber simulates real-life water exposure like spray and splashing, helping you confirm your product’s durability against moisture.

Common Scenarios for IPX34 Testing

- Outdoor lighting and vehicle lamps

- Electronics enclosures used outside

- HVAC components exposed to rain or mist

- Any device with target IP codes featuring X3 or X4 water protection

Signs You Need an IPX34 Rain Test Chamber

| Indicator | Explanation |

|---|---|

| Target IP rating includes X3 or X4 | Requires testing against spray and splash water |

| Product intended for outdoor use | Exposure to rain or wet conditions expected |

| Susceptible to water damage | To avoid short circuits or rusting |

Benefits of Using an IPX34 Rain Test Chamber

- Prevents water ingress that could harm electronics

- Ensures compliance with IEC 60529 and related waterproof test standards

- Protects product reputation by confirming weather resistance

- Simulates spray at 60° angles (IPX3) and 360° splash tests (IPX4)

Choosing an IPX34 rain test chamber means you can confidently market your product as water-resistant, perfect for the U.S. climates where rain and humidity are routine challenges.

When to Choose a Dust Test Chamber

If your products face dusty or dirty environments, a dust test chamber is a must. This is especially true for devices used in:

- Arid or desert areas

- Construction sites

- Factories with heavy particulates

- Mining and outdoor equipment

Signs you need a Dust Test Chamber:

- Your product’s IP rating target includes IP5X (dust-protected) or IP6X (dust-tight) levels.

- Your device must block fine particles to avoid damage.

- You want to ensure long-term reliability in dusty conditions.

Benefits of Dust Chambers:

| Benefit | Explanation |

|---|---|

| Prevents dust buildup | Stops dust accumulation that causes failures |

| Ensures product durability | Protects internal parts from abrasion |

| Complies with IP5X/IP6X standards | Tested to IEC 60529 & MIL-STD specs |

| Avoids overheating | Keeps cooling vents clear for performance |

Using a dust test chamber helps meet dust ingress protection standards and supports dust proof testing to keep your products safe and reliable in harsh, particle-filled environments.

Do You Need Both? Exploring Combined or Comprehensive Solutions

When your product needs protection from both water and dust, you might wonder whether to get separate IPX34 rain test chambers and dust test chambers or go for a combined solution.

Options for Multi-Test Chambers

- Separate Chambers

- Specialized for water or dust testing

- More precise simulation of each environment

- Easier to maintain and calibrate individually

- Integrated Chambers

- Perform both water ingress and dust ingress protection tests in one unit

- Save floor space and reduce equipment costs

- Convenient for testing products with multiple IP requirements (e.g., IP65, IP67)

Pros and Cons of Separate vs. Integrated Systems

| Feature | Separate Chambers | Combined Chambers |

|---|---|---|

| Test Accuracy | High, tailored to test type | Good but might compromise on specifics |

| Maintenance | Easier, specialized parts | More complex, increased downtime possible |

| Cost | Higher upfront (two systems) | Usually lower total cost |

| Space Requirement | More floor space needed | Compact footprint |

| Flexibility | Limited to one test per chamber | Versatile, multi-test capacity |

What We Recommend

- Start with your primary test need—focus on either water (IPX3/IPX4) or dust (IP5X/IP6X) depending on your product’s environment.

- Expand later with a combined chamber if your testing demands grow.

- This approach keeps initial costs low while allowing future proofing for broader environmental simulation needs.

Choosing the right path depends on your product’s target IP rating guide and testing volume. If your product is outdoors and faces both rain and dusty conditions, an integrated solution might be worth the investment. For specialized applications, separate chambers can deliver better precision.

When it comes to reliable solutions, we know how to guide you on the best fit for your testing needs.

Why Choose Dexiang as Your Testing Chamber Supplier

When it comes to IPX34 rain test chambers and dust test chambers, Dexiang stands out for reliability and quality. We specialize in manufacturing chambers that meet strict IEC 60529 compliance, ensuring your products pass waterproof test equipment and dust ingress protection standards every time.

Key Advantages of Dexiang Chambers

| Feature | Benefit |

|---|---|

| Customizable Designs | Tailored to your product size and test needs |

| Precise Compliance | Meets IPX3, IPX4, IP5X, IP6X test standards |

| Durable Construction | Long-lasting equipment built for repeated use |

| Expert Support | Guidance for selecting and operating your chamber |

Our chambers perfectly simulate real-world conditions like heavy rain sprays and dusty environments, helping U.S. businesses test outdoor lighting, automotive parts, electronics, and more with confidence.

Ready to Get Started?

Contact Dexiang for personalized advice or a quote. We’ll help you choose the right rain spray test chamber or sand and dust chamber to fit your testing needs and budget.

Trust us to support your product durability and compliance goals.

Dexiang| Instruments

As a high-tech manufacturer, we integrate R&D, design, production, and sales under one roof. Our philosophy—"Quality Ensures Survival, Integrity Drives Development, and Management Yields Efficiency"—is woven into every product we build. We continuously assimilate cutting-edge global technologies and refine our practices through years of hands-on experience.

相关推荐

- How to Choose the Right Environmental Test Chamber Manufacturer 2026

- Salt Spray vs Cyclic Corrosion Chambers Differences and Buying Guide

- Testing Standards for Salt Spray Test Chambers | ASTM B117 and ISO 9227 Guide

- Top Xenon Lamp Aging Test Chamber Standards Buyers Must Know 2026

- Xenon Lamp Aging Test Chamber Standards You Must Know Before Buying

Dexiang Environmental test chamber manufacturer All Rights Reserved.