-

Welcome to Dexiang – Your trusted partner in reliability testing equipment.

- WhatsApp:+8615112812380

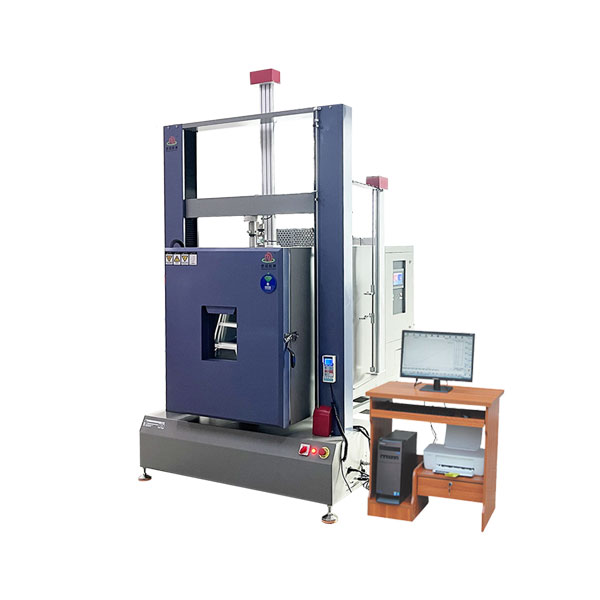

Rubber Tensile Test Machine with Temperature Chamber and Precise Control

- Category: Double Column Series, Hydraulic Universal Series, Single Column Series, Tensile Test Equipment

- |

- Date: 12/14/2023 14:56

The Dexiang Rubber Tensile Test Machine with integrated Temperature Chamber performs precise tensile testing under controlled conditions (-70°C to +200°C). Compliant with ASTM D412 & ISO 37, it delivers reliable data for automotive, seals, and elastomer R&D, ensuring material durability and quality compliance.

- Model:DX-L205

- Load Capacity Options 500 N, 1 kN, 5 kN, 10 kN – up to 50 kN

Search

Product Menu

Recommendation

Product Details

Product Overview: Dexiang Rubber Tensile Test Machine with Temperature Chamber

The Dexiang Rubber Tensile Test Machine with Temperature Chamber is a cutting-edge solution designed for precise tensile testing of rubber and elastomer materials under controlled temperature conditions. Combining a high-precision universal testing machine with a fully integrated temperature chamber, this equipment allows you to simulate real-world environmental conditions—ranging from extreme cold to high heat—to evaluate material performance accurately.

Key Benefits:

- Accurate temperature control ensures consistent and reliable test results, even at extreme temperatures.

- Versatile testing capability for a wide range of rubber compounds, elastomers, and related materials.

- Comprehensive data collection with advanced software for detailed analysis of tensile strength, elongation, and stress-strain behavior.

- Enhanced durability and stability for long-term use in demanding R&D and quality control environments.

Primary Applications:

- Testing tensile strength and elongation of rubber and elastomeric materials.

- Performance evaluation of automotive components, such as tires, seals, and belts, under thermal stress.

- Quality control testing in manufacturing plants to ensure compliance with industry standards.

- Research and development for new elastomer formulations aimed at improving thermal and mechanical properties.

The Dexiang Temperature-Controlled Rubber Tensile Tester is tailored to meet both industrial and laboratory needs, providing a dependable tool to help manufacturers and researchers maintain high product quality and innovation.

Key Features of Rubber Tensile Test Machine with Temperature Chamber

Our Dexiang Rubber Tensile Test Equipment with Temperature Chamber packs powerful features designed for accurate, reliable testing:

| Feature | Description |

|---|---|

| High-Precision Load Cells | Accurate force measurement ensures trustworthy tensile results. |

| Servo Control System | Smooth, precise control of test speed for consistent performance. |

| Integrated Temp Chamber | Rapid heating and cooling to simulate real-world conditions quickly. |

| Advanced Data Software | Easy data capture, analysis, and reporting with user-friendly interface. |

| Long-Travel Extensometers | Measures elongation accurately over large strain ranges, perfect for rubber. |

| Built-in Safety Features | Protects operator and equipment during extreme temperature tests. |

These features make it easier to conduct ASTM D412 and ISO 37 compliant tests with confidence, giving you dependable data every time. Whether you’re testing in extreme heat or cold, the temperature-controlled environment combined with precise mechanical control ensures your rubber material testing meets today’s demanding standards.

Technical Specifications of Rubber Tensile Test Machine with Temperature Chamber

Our Dexiang Rubber Tensile Test Machine with Temperature Chamber comes loaded with flexible specs to fit your testing needs. Here’s a quick overview:

| Specification | Details |

|---|---|

| Load Capacity Options | 500 N, 1 kN, 5 kN, 10 kN – up to 50 kN |

| Temperature Range | -70°C to +200°C (high/low temperature testing) |

| Test Speed & Accuracy | 0.001 to 500 mm/min; speed accuracy ±0.5% |

| Chamber Dimensions | Standard: 400mm(L) x 400mm(W) x 400mm(H) |

| Temperature Uniformity | ±1.5°C across chamber for precise testing |

| Control System | Servo motor-driven load control with touch panel |

| Data Output & Software | Real-time data logging, USB & Ethernet ports, compatible with Windows OS |

With precise load cells and a responsive servo system, our machine delivers reliable tensile strength and elongation data every time.

The temperature chamber offers rapid heating and cooling to test rubber under controlled environments mimicking real-world conditions. Its spacious size fits various rubber specimen sizes, and maintains uniform temperature for consistent results.

You get straightforward control with our integrated software—easy data acquisition, analysis, and export options make running and reviewing tests simple for your team.This seamless integration of mechanical testing with precise environmental control is a core strength of our expertise as an environmental test chamber manufacturer.

Overall, this setup ensures you have the right tools for accurate, repeatable rubber tensile tests —whether it’s for automotive, industrial, or research uses across the U.S. market.

Compliant Standards for Rubber Tensile Test Machine with Temperature Chamber

Our Rubber Tensile Test Machine with Temperature Chamber meets key industry standards to ensure reliable and accurate results. It fully complies with ASTM D412, the benchmark for testing vulcanized rubber’s tensile properties. It also supports ISO 37, which covers tensile stress-strain testing for rubber materials.

Beyond these, the system is designed to handle related testing standards such as ASTM D638 for plastics and ISO 6892 for metals, making it versatile for various elastomer and material testing needs. This compliance guarantees your tests align with widely accepted quality and safety protocols, essential for manufacturers and labs across the US.

Applications of Rubber Tensile Test Machine with Temperature Chamber

Our Rubber Tensile Test Machine with Temperature Chamber is perfect for checking the tensile strength and elongation of various rubber materials. It handles performance testing under extreme temperatures, making it a solid choice for automotive and industrial parts that face tough conditions.

Common uses include:

- Quality control for tires, seals, and belts

- R&D for new elastomer formulas

- Testing rubber components designed to work in hot or cold environments

This temperature-controlled rubber tensile tester ensures reliable results no matter the climate, helping manufacturers meet strict standards and improve product durability.

Advantages of Dexiang Rubber Tensile Test Machine with Temperature Chamber

When you choose the Dexiang Rubber Tensile Test Machine with Temperature Chamber, you get reliable performance and smart features designed to meet tough testing needs.

- Superior Temperature Uniformity and StabilityOur integrated temperature chamber ensures consistent heating and cooling, delivering precise and repeatable results across your rubber tests—even under extreme conditions.

- User-Friendly Interface and Customizable TestsThe intuitive software makes setup quick and easy. You can tailor test parameters to fit different rubber materials and testing standards without hassle.

- Robust Construction for Long-Term UseBuilt with durable materials and high-quality components, this tester stands up to frequent use in busy labs or production environments with minimal maintenance.

- Competitive Pricing with After-Sales SupportWe offer great value without compromising quality. Plus, our knowledgeable customer support team is ready to help with installation, training, and any questions after your purchase.

These advantages make the Dexiang model a top choice for companies in automotive, industrial manufacturing, and quality control in the U.S. looking for a temperature-controlled rubber tensile tester that’s precise, easy to use, and built to last.

Accessories and Options for Rubber Tensile Test Machine with Temperature Chamber

To get the best results and fit your testing needs, Dexiang offers several accessories and optional upgrades:

| Accessory / Option | Description | Benefits |

|---|---|---|

| Specialized Grips | Custom grips designed for different rubber types and sizes | Secure hold, prevents slip or damage |

| Optical/Video Extensometers | Non-contact strain measurement using cameras | Accurate elongation data, ideal for delicate samples |

| Humidity Control Modules | Adds precise humidity regulation inside the chamber | Tests rubber performance in different climates |

| Software Upgrades | Advanced data analysis, report customization, remote control options | Enhances usability and data tracking |

These accessories make your rubber tensile strength tester with climate control more versatile, ensuring you can handle a wider range of rubber materials and environmental conditions. Whether it’s thermal tensile testing or controlled environment tensile testing, these options add value and precision to your lab or production line.

Installation and Calibration

Setting up the Dexiang Rubber Tensile Test Machine with Temperature Chamber is straightforward and designed for quick start-up. We provide clear setup requirements that fit most lab environments here in the U.S., including space, power, and ventilation needs.

Our team offers on-site installation to make sure your machine is correctly assembled and fully operational from day one. During installation, we also provide hands-on training for your staff, covering everything from basic operation to advanced use of the temperature-controlled features. This helps your team get comfortable and confident with the machine right away.

Calibration is key to reliable results. We follow strict calibration procedures following ASTM and ISO traceability standards, ensuring your tensile tester meets or exceeds accuracy requirements. Regular calibration services are available to maintain performance and compliance over time.

With Dexiang, you get not just a top-tier Rubber Tensile Strength Tester with Climate Control but also full support to keep it running smooth and precise.

Why Choose Dexiang Rubber Tensile Test Machine with Temperature Chamber

When you pick Dexiang, you get more than just a temperature-controlled rubber tensile tester — you get a trusted partner with real expertise.

What Sets Dexiang Apart?

| Feature | Benefit |

|---|---|

| Manufacturer Expertise | Years in testing equipment production, ensuring reliable, accurate machines tailored for the U.S. market. |

| Customization Options | Flexible test protocols, grips, and software to match your exact rubber and elastomer testing needs. |

| Global Support & Warranty | Fast technical support, easy access to replacement parts, and warranty coverage for peace of mind. |

We understand U.S. industries demand precise results under varying conditions. That’s why our thermal tensile testing machines for elastomers are built robust, user-friendly, and backed by solid customer service.

Choosing Dexiang means getting a rubber tensile strength tester with climate control you can count on today and tomorrow, tailored for your workflow and quality standards.

FAQ: Common Questions on Operation, Maintenance, Compatibility, and Troubleshooting

Q: How do I operate the Rubber Tensile Test Machine with Temperature Chamber?

A: Operating is straightforward. Power on the system, set your test parameters through the user-friendly software, and the machine handles the rest. The integrated temperature chamber allows easy control of testing environment up to high/low temperature ranges, perfect for ASTM D412 or ISO 37 compliant tests.

Q: What maintenance does the equipment require?

A: Regular maintenance includes cleaning grips and chamber, checking load cell calibration, and keeping software updated. Routine inspections of seals and chamber components ensure stable temperature control. We recommend annual professional calibration to maintain accuracy.

Q: Is this machine compatible with ASTM D412 and ISO 37 testing standards?

A: Yes, our temperature-controlled rubber tensile tester fully supports ASTM D412 for vulcanized rubber and ISO 37 tensile stress-strain methods. It also meets other standards like ASTM D638 and ISO 6892, making it versatile for elastomer testing.

Q: Can I troubleshoot temperature uniformity issues?

A: If you notice uneven temperature, check the chamber’s ventilation and heating/cooling systems first. Our advanced climate control keeps uniformity tight, but ensure the specimen is placed correctly. Contact support for detailed troubleshooting or calibration support.

Q: What if the load readings seem inconsistent?

A: Inconsistent load results might be due to improper grip installation or load cell errors. Double-check grips are suited for rubber specimens and tightened properly. If problems persist, recalibrate the load cell or consult our technical team.

Q: How often should I update the software?

A: Keep your testing software up to date with our latest releases. Updates improve data acquisition, analysis features, and compatibility with new testing protocols. We send notifications for major updates or you can check online regularly.

Q: Does the machine support additional accessories?

A: Yes, the system supports optical extensometers, humidity control modules, and specialized grips for different rubber types. Adding these options enhances testing flexibility and precision.

Q: Who do I contact for technical support?

A: Reach out to our dedicated U.S.-based support team via phone or email for quick assistance. We provide training, troubleshooting guides, and onsite support if needed to keep your machine running smoothly.

Have a question? Don’t hesitate to contact us anytime for expert help with your Rubber Tensile Strength Tester with Climate Control.

Related Products

To get the most from your Rubber Tensile Test Machine with Temperature Chamber, consider these complementary tools:

- Universal Tensile Testers – For broader material testing, including plastics and metals.

- Aging Ovens – Ideal for simulating environmental exposure and accelerated aging of rubber samples.

- Hardness Testers – Measure the hardness of elastomers to ensure quality and consistency.

- Optical Extensometers – Enhance accuracy when measuring elongation without contact.

- Humidity Control Modules – Add precise moisture control for more realistic environmental testing.

These related products work hand-in-hand with your temperature-controlled rubber tensile tester, helping you cover all bases in material performance and quality assurance.

Contact Us / Request a Quote

Ready to upgrade your testing setup with our Rubber Tensile Test Machine with Temperature Chamber? Reach out today! Whether you want a detailed quote, product info, or support, we’re here to help.

- Phone: Call us at (800) 555-1234 for quick answers

- Email: Send your questions to sales@dexiangtesting.com

- Contact Form: Visit our website and fill out the request form to get personalized pricing and service options

We’re committed to providing reliable, temperature-controlled rubber tensile testers tailored to your needs. Contact Dexiang now and experience top-tier testing equipment backed by expert support across the United States.

Dexiang| Instruments

As a high-tech manufacturer, we integrate R&D, design, production, and sales under one roof. Our philosophy—"Quality Ensures Survival, Integrity Drives Development, and Management Yields Efficiency"—is woven into every product we build. We continuously assimilate cutting-edge global technologies and refine our practices through years of hands-on experience.

© 2025. All Rights Reserved. cntestingchamber.com